Film hybrid 30/60 60KW Power Supply

Price on request

The Film hybrid 30/60 60KW Power Supply is a new, innovative type of power source for the film industry.

The concept

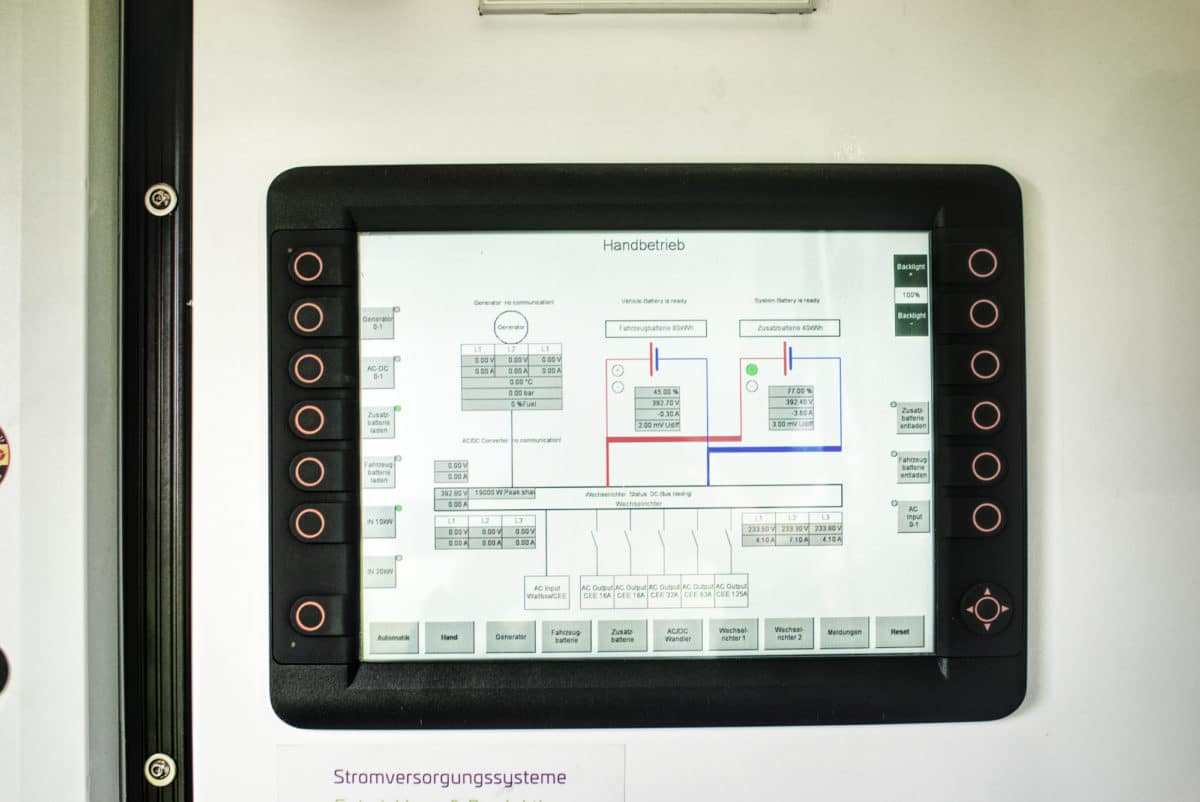

The central element is the 110kWh battery of the electric vehicle, which is used to drive the vehicle and to operate the inverters. The inverters have an output of 60KW distributed over 3 phases of 20KW each (24kVA) and can use electricity from different sources at the same time. Any existing grid power connection can be integrated into the supply via bidirectional inputs/outputs of each inverter. This means that grid connections can now also be used for the power supply, which would not have been sufficient under previous circumstances, e.g. to supply larger projectors. Typical Type 2 charging stations (11KW and 22KW) can also be used in this function.

In addition, the inverters have a phase balancing function. This means that the 3 phases of a possible mains feed are loaded evenly, even if the phases on the output side are loaded asymmetrically. (Example: an 18KW HMI is supplied with 18KW on the output side, while three phases are evenly loaded with 6KW each on the feed side; in this example the battery is not used at all).

ANY existing grid connection increases the performance & capacity of the FH30/60. More capacity from a grid feed is always used to charge the batteries.

If the electrical resources are not sufficient or the battery*s state of charge is running low, a 20kVA range extender starts. The range extender is limited to 15kW for continuous operation, uses C.A.R.E. Fuel and meets EU Stage V emissions standards.

A photovoltaic system always supplies the control-unit and the vehicle’s systems.

What does the 30/60 stand for?

The FH30/60 has enough energy on board to continuously supply 30KW for a 10-hour shooting day. Combined battery capacity and range extender capability with C.A.R.E. fuel is 300kWh (with AC feed- in, of course, correspondingly more). The peak continuous power is 60KW.

This information is only partially comparable with conventional diesel generators: while a classic generator consumes diesel even when idling, this is not the case with the FH30/60. In addition, excess energy is immediately stored in the battery. The 300kWh of the FH30/60 therefore go much further than the same capacity would do with a conventional unit. A conventional diesel unit has so far been loaded with a maximum of 80% for peak continuous output. The FH30/60 can be fully loaded permanently. Individual phases can also be permanently fully loaded, since the FH30/60 does not care unbalanced loads due to the phase balancing.

Battery technology

The battery technology is Lithium Iron Phosphate (LiFePO4 or LFP in short). This type is very safe, e.g. insensitive to mechanical damage or short circuits. LFP batteries are also durable (up to 5000 full cycles) and tolerate temperatures much better than their Lithium Ion relative. The environmental balance is also significantly better: no toxic heavy metals such as cobalt, cadmium or nickel are used in LFP and all metals used can be 100% recycled (unlike other material combinations). More than 90% of the electrode materials and the polymer separator can also be recycled.